Did you know? Moisture Testing

Did you know, not all moisture tests are created equal? Common moisture tests used in the waterproofing industry all have their place, but they provide very different data.

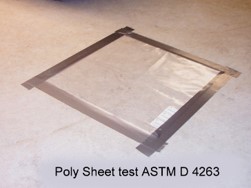

ASTM D4263, also known as the Plastic Sheet Method, is a qualitative test that is often used in deck coating installations. This test calls for a polyethylene plastic sheet to be adhered to the concrete substrate for a period of 18 – 24 hours and checked for visible signs of moisture which can indicate a slab’s moisture content may be too high for a non-permeable membrane.

ASTM1869, or the calcium chloride test, is a 72-hour test which will provide how many pounds of moisture vapor is exiting a 1000 sq. ft. area in 24 hours. Common in the flooring industry, this test consists of weighing a disk of calcium chloride before and after the disk sits on a prepared surface for 24 hours. In most cases, this test measures the upper ¼” to ½” of the concrete surface.

ASTM F2170, or the relative humidity test, measures relative humidity within the concrete slab, typically 40-50 % the overall depth of the slab. A hole is drilled into the slab, and a sensor is placed in the bottom. This 24 hour test provides the RH% deep within the slab which can be used as a predictor of future membrane moisture issues.

ASTM F2659, uses a handheld moisture meter to determine the percentage of moisture in the upper surface of concrete. While these meters work instantaneously, it is generally accepted that they are measuring only the upper 1/2” or so of the concrete.

Manufacturers of non-permeable membranes will generally reference thresholds for these tests in their published technical documents.

To ensure that moisture testing yields the results needed to make accurate system recommendations, it is important to use the correct test, follow the testing protocols outlined in the ASTM guidelines, and always consult the manufacturers guidelines concerning acceptable moisture levels, prior to installing any non-permeable waterproofing materials.